- Blucor's Newsletter

- Posts

- The Future of AI Recruiting in Manufacturing: Trends and Predictions

The Future of AI Recruiting in Manufacturing: Trends and Predictions

Manufacturing is entering a new hiring era where data, automation, and human insight intersect. The same predictive systems that optimize production lines are beginning to shape how factories find, evaluate, and retain talent. As Industry 4.0 matures, recruiting is no longer a back-office function. It is becoming a strategic lever for competitiveness.

TL;DR:

AI recruiting in manufacturing is shifting from reactive hiring to predictive workforce planning. Expect three major trends: predictive skill-matching, autonomous recruiting systems, and integration between HR and production data. Together, these will define how manufacturers attract and manage talent in the next decade.

Predictive Skill-Matching: From Job Descriptions to Data-Driven Fit

Traditional hiring relies on resumes and gut instinct. Predictive analytics changes that equation. By analyzing performance data, training outcomes, and career trajectories, AI can forecast which candidates are most likely to succeed in specific roles.

For example, a plant that tracks operator efficiency and safety metrics can feed that data into a predictive model. The system learns which skill combinations correlate with high performance, then applies that insight to future applicants. Instead of screening for years of experience, recruiters can focus on measurable competencies such as machine calibration accuracy, maintenance response time, or adaptability to automation tools.

This shift supports a skill-based labor market. Candidates are evaluated on what they can do, not just where they have worked. For manufacturers facing labor shortages, predictive skill-matching expands the talent pool by identifying adjacent skills that can transfer across roles.

Autonomous Recruiting Systems: The Always-On Hiring Engine

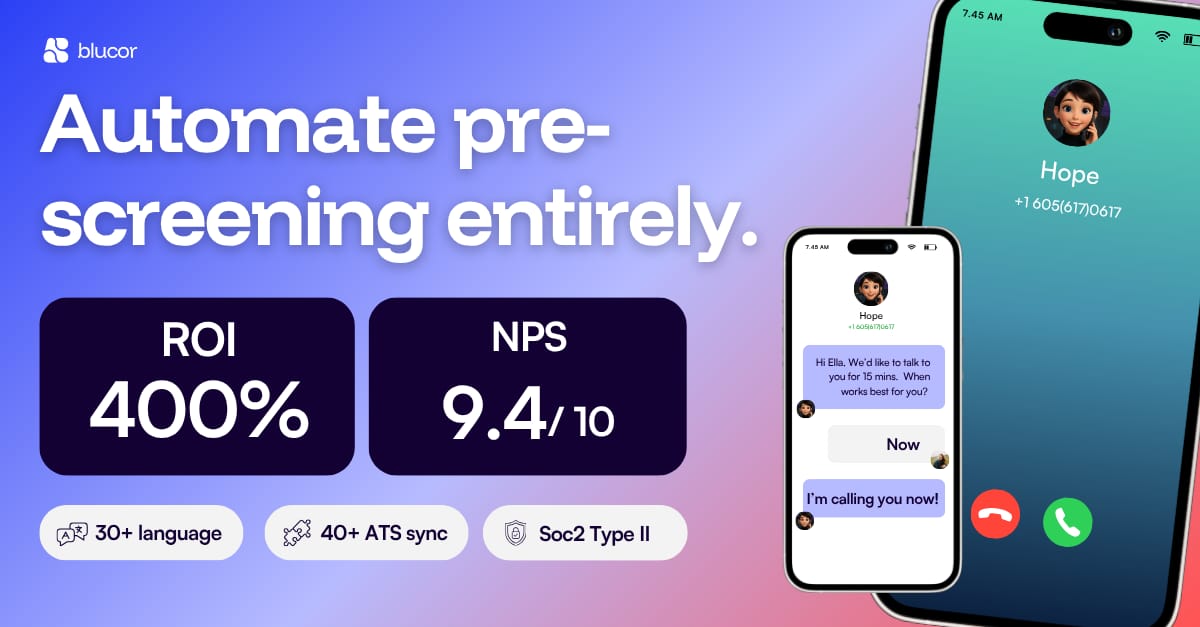

AI recruiting agents are evolving from simple screeners into autonomous systems that manage entire hiring cycles. These agents can source candidates, conduct phone interviews, rank applicants, and update the ATS automatically. In high-volume environments like manufacturing, where hundreds of applications arrive for each opening, this automation removes manual bottlenecks.

Imagine a system that runs 24/7, speaks 30+ languages, screens for certifications, and schedules interviews without human intervention. Recruiters step in only to review top candidates or adjust criteria. The result is faster hiring, lower cost per hire, and a smoother candidate experience.

Manufacturers using AI-driven screening tools such as BlancAI report time and cost savings of around 67% and candidate satisfaction scores above 9 out of 10. As these systems integrate deeper with HR platforms, they move from task automation to decision support, flagging potential turnover risks or recommending internal mobility options before a vacancy even opens.

Integrating HR and Production Data: The Next Frontier of Workforce Planning

The next wave of AI recruiting will merge HR analytics with production data. When workforce planning connects directly to output metrics, manufacturers can predict labor needs with precision. For instance, if a production line’s throughput increases by 15%, the system can forecast the additional operators required, identify internal candidates ready for upskilling, and trigger external recruiting automatically.

This integration creates a digital workforce ecosystem where hiring, training, and scheduling operate as one continuous loop. Predictive hiring becomes part of operational planning, not a separate HR process. The payoff is agility. Factories can scale teams up or down in sync with demand, reducing overtime costs and minimizing downtime.

Forward-looking manufacturers are beginning to explore this model. They use AI to simulate workforce scenarios, test the impact of automation on staffing, and plan reskilling programs months in advance. The result is a more resilient, data-informed approach to talent management.

Outlook: Competitive Advantage Through Predictive Hiring

Manufacturers that treat AI recruiting as a strategic capability that reduces cost and drives growth will gain a lasting edge. Predictive analytics helps them anticipate skill gaps before they emerge. Autonomous systems keep hiring pipelines active even during labor shortages. Integrated data aligns workforce strategy with production goals.

The future of work in manufacturing depends on how well companies connect people, process, and prediction. Those who invest early in AI recruiting infrastructure will not only fill roles faster but build smarter, more adaptable teams ready for the next industrial shift.

Conclusion

AI is redefining what it means to hire in manufacturing. Predictive skill-matching replaces guesswork with evidence. Autonomous systems free recruiters to focus on people, not paperwork. Integrated data turns hiring into a strategic function tied directly to output and growth. Manufacturers that act now will set the standard for how the future of work takes shape on the factory floor.

Call to Action:

Book a demo or start a free trial to see how predictive hiring can connect your workforce strategy with production performance.